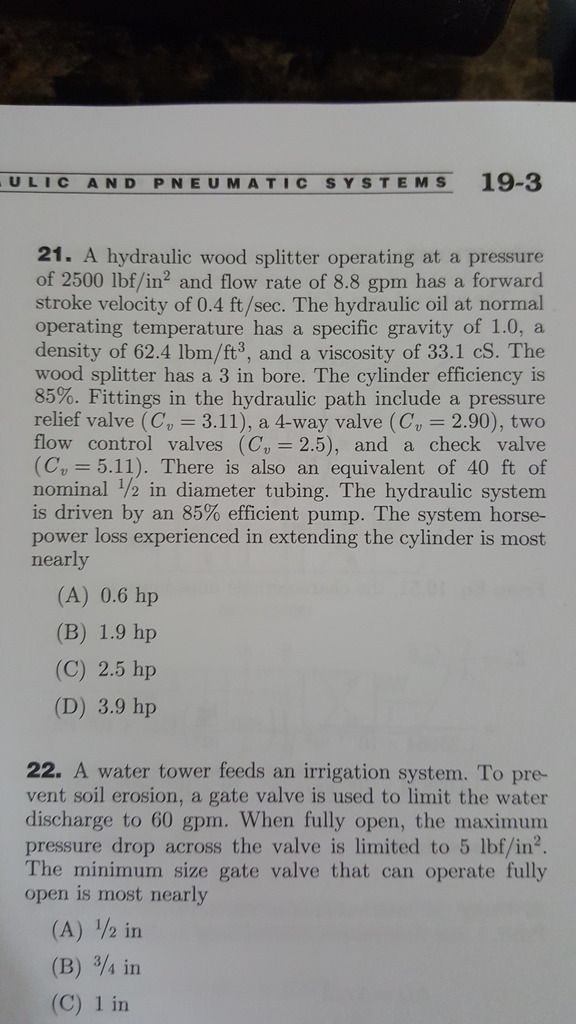

Question asks for Power LOSS.

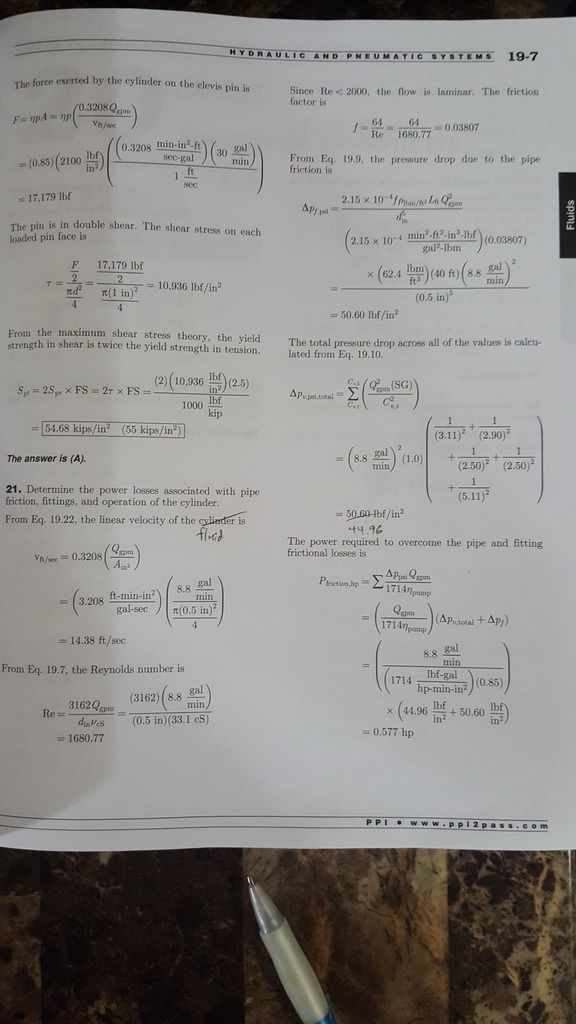

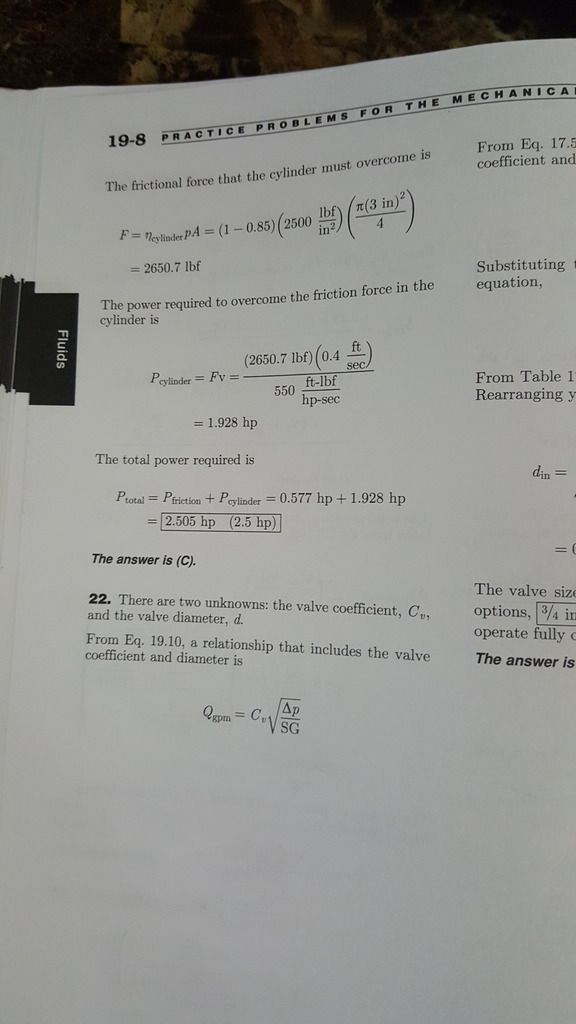

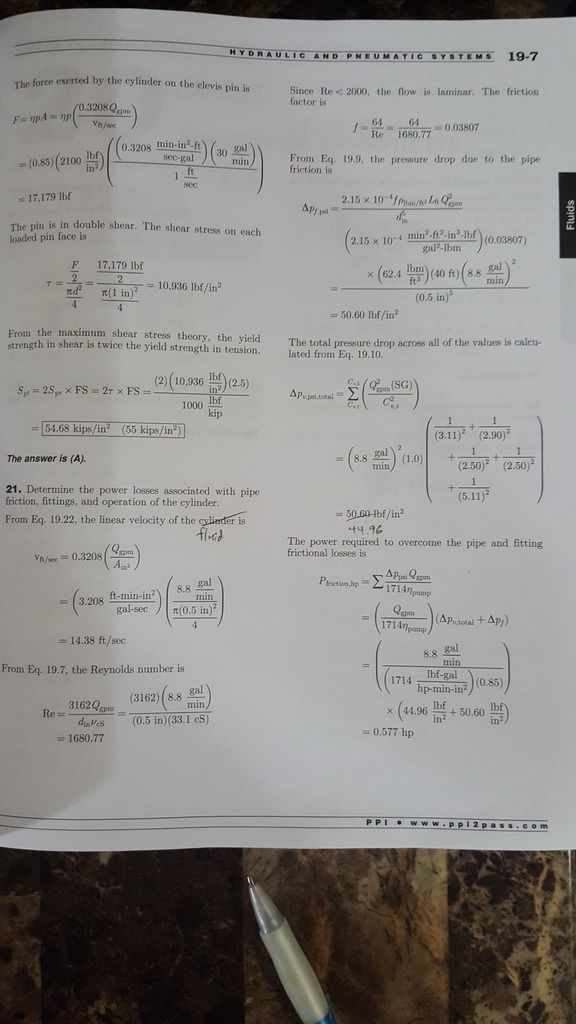

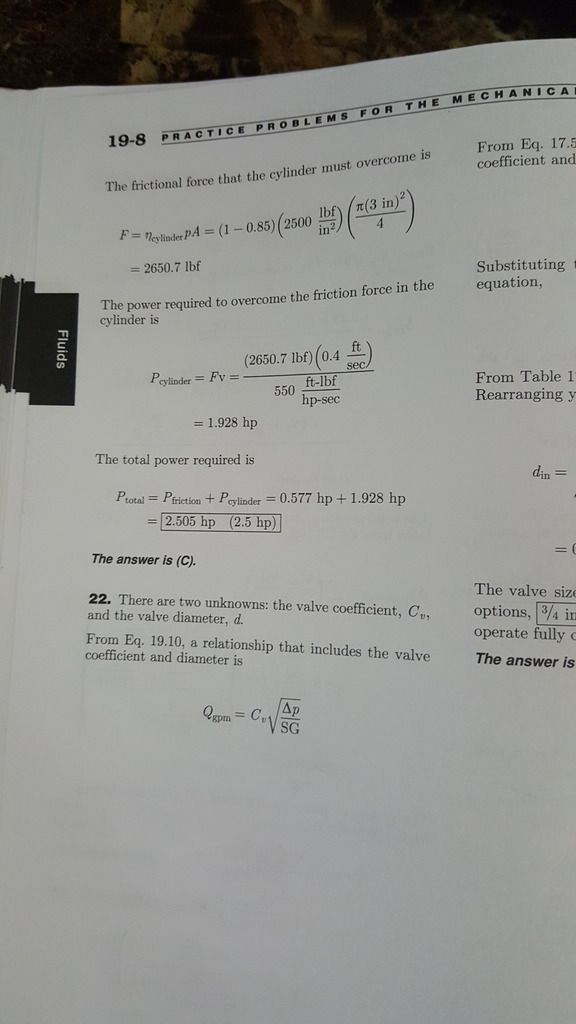

For the cylinder power loss term, this is (1-efficiency)*pressure*Area*Velocity. Looks like the solution mistakenly has written "n_cylinder", instead of "(1-n_cylinder)" at the top of p. 19-8. Well that's confusing!

For the fittings/hose power loss term, this includes: power losses due to friction in the valves and lengths of hose (taken as a whole using Table 18.5), AND the losses in the pump. So the approach taken in the solution includes the inefficiency of the pump by increasing that term by 1/eff_pump. If you are wondering why you aren't just looking for the (1-eff_pump) it's because the entire pump power dedicated to overcoming fittings/hose friction is a part of the SYSTEM LOSSES, including losses in the pump itself.

Efficiency calculations, in general, are all about perspective, and whether you know the input power (Pin) or output power (Pout) to begin with. If you know the input power, you can subdivide it into: power applied Pin*(eff), and power lost Pin*(1-eff), and they both sum to Pin. If you know power output, and want to know what power input is required, you are only looking at the "power applied" part: Pout = Pin*(eff), or rearranged: Pin = (1/eff)*Pout.

SO, in the first term (cylinder losses), you knew the ideal Pin (p*A*V), and in the second term (fittings/hose/pump) you knew the ideal Pout, which explains why they are treated differently.