The following calculations and terms are important in determining signal timing plans:

Critical Volume(Vc)

During any given signal phase, prescribed sets of traffic movements are given the right-of-way. The phase diagram shown on the Signal Operations page is a useful illustration associating sets of traffic movements to their respective phases. For each phase, one of the movements will have the maximum traffic volume

per lane and this volume is known as the

critical lane volume. The sum of all critical lane volumes served in a cycle is known as the critical volume (V

c).

When calculating cycle lengths and green times, it is much easier if you are working with a single type of vehicle. This is because different types of vehicles behave differently and vehicles executing different turning movements behave differently. A car turning left is generally not going to accelerate as quickly as a car going straight. Therefore, before the critical volume is calculated, it is important to make sure that all of the volumes are in through car equivalent units (tcus). TCUS are generated by multiplying the original volumes by factors to account for the added congestion that turners, both right and left, add to the traffic flow. Turners add congestion generally because they must slow down to go around the corners, and in the case of left turners, there are situations in which they block through lanes while waiting to turn. Tables with tcus factors can be found

here. We must also adjust for heavy truck traffic. Trucks take more physical space on the roadway than cars, and they generally move more slowly, especially in cities. For these reasons, we must divide the volumes by a heavy vehicle factor (f

HV). This factor is given by:

Where %HV is the percentage of heavy vehicles.

Example

Assuming the volumes have already been factored for tcus and heavy vehicles, use the volumes for each movement shown in the figure to find the critical volume.

Solution

To find the critical volume, we must first find the critical lane volumes. This is the highest movement volume in the phase, divided by the number of lanes. The critical volume is the sum of the critical lane volumes.

The critical volume is: V

c =160+280+365 =

805 v.p.h.

Top

Headway (h) and Saturation Flow Rate (s)

Saturation flow rate is the number of vehicles served by a lane for one hour of green time. In order to determine saturation flow rate, we must know the headway and saturation headway.

Headway is the time interval between the passage of successive vehicles moving in the same lane measured from head to head as they pass a point on the road.

Saturation headway is the headway of the vehicles in a "stable moving platoon" passing through a green light. A stable moving platoon is a group of vehicles that are traveling, but not really moving in relation to each other (i.e. all going the same speed). The headway of the first four vehicles leaving an intersection after a red light will have a higher value so the saturation headway will not be realized until the 4

th or 5

th queued vehicle leaves the intersection.

If every vehicle requires a time equal to the saturation headway (h), in seconds, to be serviced at a signalized intersection, then the maximum number of vehicles that can be serviced in an hour of green is given by the equation

s = 3600/h, where s is saturation flow rate, in veh/hr.

Top

Lost Time

Unfortunately, intersections are not constantly in use. There may always be cars waiting for the light, but there are times when there is no one actually in the intersection. Lost time is a measure of this no-use time, and it takes into account lost time at the beginning and ends of a phase. At the beginning of the green time, actual headway will be relatively longer than saturation headway for the first four vehicles, which includes driver reaction time and the time necessary for acceleration. In the graph below, the horizontal line at "h" is the saturation headway.

Startup Lost Time Graph

The sum of the time difference between the saturation headway and the first four headways is known as

start-up lost time. In addition to start-up lost time there is lost time when the right of way changes, known as

clearance lost time. It is the time between the last vehicle entering the intersection and the initiation of green on the next phase.

So the total lost time (t

L ) in one phase is the sum of

start-up lost time and the

clearance lost time and the total lost time for a cycle is the lost time per phase multiplied by the number of phases per cycle.

Desired V/C Ratio (v/c)des

The v/c ratio is the ratio of current flow rate to capacity of the facility. It is an indicator of the quality of the operations at an intersection.

v/c

= (rate of flow) / capacity

v/c ratio is part of the design criteria and is a value we are hoping to attain when timing a traffic signal. To test this value at an existing intersection, we can get the flow rate from traffic counts and

capacity can be calculated based on the signal timing plan.

A ratio that is greater than 1.0 predicts that the facility will fail, because it is unable to discharge the demand arriving at the section. Usually a value between 0.85 to 0.95 is considered desirable for design purposes.

Peak Hour Factor (PHF)

The relation between hourly volume and the maximum probable rate of flow within an hour is defined by the peak hour factor (

PHF).

PHF

= Hourly Volume / Maximum rate of flow

The Highway Capacity Manual (HCM) recommends a minimum time interval of 15 minutes for most operational and design analysis. So the

PHF can be given as:

- V = Peak hourly volume (veh/hr)

- V15 = maximum 15 minute volume within the peak hour (veh).

For 15-minute periods, the maximum value of the PHF is 1.00 and the minimum value is 0.25. The normal range of values is between 0.70 and 0.98.

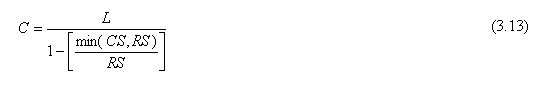

Cycle Length Calculation

Cycle length is the amount of time from when a movement first is given the right of way until that movement receives it again. It is calculated using the equation below. Generally, agencies have some minimum cycle length below which they will not program their signals. This is because there would be too many phases per hour, and therefore too much lost time. For our examples, we will use 45 seconds as a minimum.

N = Number of phases in one cycle

tL = Total lost time per phase (sec)

Vc = Critical volume (vph)

PHF = Peak Hour Factor

v/c desired = Desired volume/capacity ratio

h = Saturation Headway (sec)

Green Time Calculations

Once the cycle length has been established, it is necessary to determine the

green split, or how long each phase will have the right of way (green indication). First we must calculate the

effective green time, which is the time that a movement is going, regardless of the indication shown (i.e. people going on yellow or not going at the start of a phase). Effective green time is calculated using the equation below.

- gi = Effective green time (sec)

- Vci = Critical volume for phase (veh/ln·hr)

- Vc = Total critical volume (veh/ln·hr)

- C = Cycle Length (sec)

- L = Total lost time (tL · N) (sec)

Actual green time is based on the effective green time, and takes into account the lost time and the all-red and yellow time to come up with a value to use in programming the signal. Actual green time is calculated using the equation below.

- Gi = Actual green time (sec)

- tL = Lost time per phase (sec)

- Yi = Yellow and all-red time (sec)

Capacity

Intersection capacity is complex and involves many different factors. It is outlined in detail in the Highway Capacity Manual, but we will give it a cursory treatment.

We have an equation to estimate the lane capacity at a signalized intersection. To find the approach capacity, add up the lane capacities. The equation is as follows:

- ci = Capacity of one approach lane (passenger cars per lane per hour)

- h = Saturation headway (2 sec for our cases)

- gi = Effective green time for the approach (sec)

Variables defined previously

- C = Cycle length (sec)

The equation gives us the capacity in passenger cars with a normal headway. However, large trucks and turning vehicles will not necessarily have normal headways. For that reason, when we are comparing volumes to capacities (such as with the v/c ratio) we must use volumes that have been

factored for heavy vehicles and turning movements.