Excuse the crude adobe job, but this was my method. There is no way that I can see that the head won't increase.

View attachment tyKTLBp.pdf

View attachment tyKTLBp.pdf

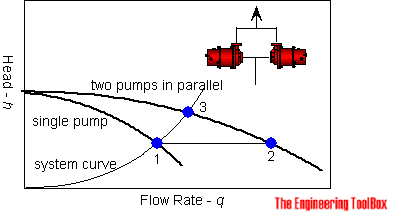

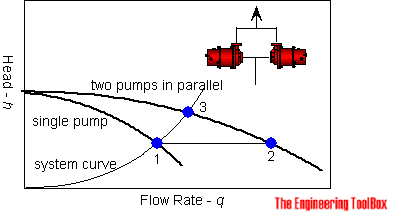

From engineering toolbox:Forgot to add. So if you see that the operating point of 3 pumps in parallel is 500-520 units (lets gpm as you pointed out its unit less). If you were to measure the flow at the discharge header on 3 pumps you would measure the 500-520 gpm. What would you measure if you took a flow measurement directly at the discharge of each pump? 500 to 520 divided by 3 so ~170 GPM which is where I get the 167 GPM.

That's exactly what I am doing! The flow does not triple because it most follow the system curve!. You tripled the flow and found where it intersected the y-axis for head. This assumes there is absolutely no friction and the system curve is flat. See below it's kind of sloppy, but hopefully it makes some sense.From engineering toolbox:

Pumps in Parallel - Flow Rate Added

When two or more pumps are arranged in parallel their resulting performance curve is obtained by adding the pumps flowrates at the same head as indicated in the figure below.

Centrifugal pumps in parallel are used to overcome larger volume flows than one pump can handle alone.

Note that for two pumps with equal performance curves running in parallel

- for two identical pumps in parallel and the head kept constant - the flowrate doubles compared to a single pump as indicated with point 2

- the head for each pump equals the head at point 3

- the flow for each pump equals half the flow at point 3

Well it doesn't change the answer that would be selected as Audi points out using logic 65 ft is really the only thing that is event remotely feasible. Personally I just thought it was a bit wacky of a best choice and while Audi may think I'm crazy at least I'm not the only one that is!I see what you're saying now. Hammering through questions I didn't question it and just took 3x the flow rate and moved on. I didn't look too closely at what a properly plotted 3xQ would look like.

I'm afraid I'm not any help, then. Perhaps you can report it to NCEES and hope to save future engineers the headache if they verify the graphs (unless I'm also now missing something!).

Enter your email address to join: