I tackled a couple of small tile projects this weekend. The back entry and the drywall above the master shower had some water damage that needed addressing. Pulled sheetrock/subfloor out. Replaced with green board/plywood-greenboard and layed tile. The floor was easy. Only three cuts. I had the bright idea to lay the shower wall at 45 degrees. That was a bear. I broke a borrowed tile cutter and got to borrow my BIL powered hand saw. Couldn't have done it without the hand saw.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Home Improvement/Repair Questions

- Thread starter knight1fox3

- Start date

Help Support Professional Engineer & PE Exam Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Road Guy

Well-known member

like a grinder with a cut off wheel? (hand saw)

Back when the residential building economy was in the tank I picked up a really sweet tile saw for a bunch of tile projects fairly cheap $250 bucks) this was a beast of a saw. Sadly I sold it when I moved, wish I still had it cause the wife is wanting to tile our bathroom, for some reason a lot of the master bathrooms have carpet in them out here.. but wish I had the saw for this job so I don't have to buy one or rent one

Back when the residential building economy was in the tank I picked up a really sweet tile saw for a bunch of tile projects fairly cheap $250 bucks) this was a beast of a saw. Sadly I sold it when I moved, wish I still had it cause the wife is wanting to tile our bathroom, for some reason a lot of the master bathrooms have carpet in them out here.. but wish I had the saw for this job so I don't have to buy one or rent one

Crown molding with 22 1/2 degree bevel cuts for a window cornice was my nemesis this weekend. I couldn't figure out one end with a single bevel miter saw, and the degrees that the lookup tables were giving me were very clearly off.

Dexman PE PMP

Internationally PMP'n his PE-ness

My miter saw has the angles pre-marked for crown molding. It made it 1000x easier not needing to calculate it.

jeb6294

Well-known member

My Craftsman saw has pictures and a chart in the instruction book for crown molding, i.e. if you want the inside of this corner, set this to X degrees and that to XX degrees.

I got to have someone come over this weekend and dig up the front of our house to figure out why the sewer was running out from underneath the front patio. There was a clog, but apparently everything has settled enough over the 50 years since the house was built that the lateral has a belly in it. The clog was bad enough that everything was coming out the joint where the belly way. They cleared the clog as a temporary Band-Aid and we'll have to have them come out and do a more permanent fix once the weather improves. One fortunate thing it that, even though we have a full basement, the sewer line is a high line (elevated about 5-ft high where it exits the basement) so it's only about 3-ft deep. When the nimrods built the house, they also went out about 8-ft and then put in a 90....who puts a 90 in a sewer lateral?

I got to have someone come over this weekend and dig up the front of our house to figure out why the sewer was running out from underneath the front patio. There was a clog, but apparently everything has settled enough over the 50 years since the house was built that the lateral has a belly in it. The clog was bad enough that everything was coming out the joint where the belly way. They cleared the clog as a temporary Band-Aid and we'll have to have them come out and do a more permanent fix once the weather improves. One fortunate thing it that, even though we have a full basement, the sewer line is a high line (elevated about 5-ft high where it exits the basement) so it's only about 3-ft deep. When the nimrods built the house, they also went out about 8-ft and then put in a 90....who puts a 90 in a sewer lateral?

$35.00

DERRACO ENGINEERING GUARD PRESS for Knife Makers great for making hidden tang knives.

Derraco Engineering

$101.99

Automatic Level 32X Optical Transit Survey Auto Level High Precision Level Gauge Measure Meter Machine

Yae First Trading

$109.00

$150.00

Texas Instruments TI-84 Plus CE Color Graphing Calculator, Black

ETrade (We record Serial number to prevent FRAUD)

$166.99

$175.00

Texas Instruments TI-Nspire CX II CAS Color Graphing Calculator with Student Software (PC/Mac)

Amazon.com

the secret to this is cutting crown molding upside down where the mounting face is against the back stop. then the only angle is the 45 degree corner. use a sharp blade.Mine does not, and with it not being a double bevel, it is that much harder.

jeb6294

Well-known member

I also make sure to keep all my scrap pieces so I can do a practice cut if I'm not sure and also to test fit cuts...sometimes the saw may need to be adjusted a degree or two to get a better joint.

Dexman PE PMP

Internationally PMP'n his PE-ness

^^^ Just use caulk to fill the gaps. You need it to fill the nail holes anyways. All my crown molding is 9' up, no one can tell a difference.

Road Guy

Well-known member

crown is tough, when I worked at Home Depot we sold a compound miter saw that had the angles marked on it for crown (I think it was a Ryobi?) we couldn't keep it in stock (even though it was a Ryobi)

my grandfather helped me put some up in a townhouse we bought a long time ago, he basically would use a coping saw.

Its an acquired skill for certain..

my grandfather helped me put some up in a townhouse we bought a long time ago, he basically would use a coping saw.

Its an acquired skill for certain..

Dexman PE PMP

Internationally PMP'n his PE-ness

The bigger challenge is when you discover your ceiling/walls aren't straight and/or square. I used more caulk filling the gap along the length of the molding than at the corners. I also did a 3-piece molding and had to fill the gaps in between the pieces.

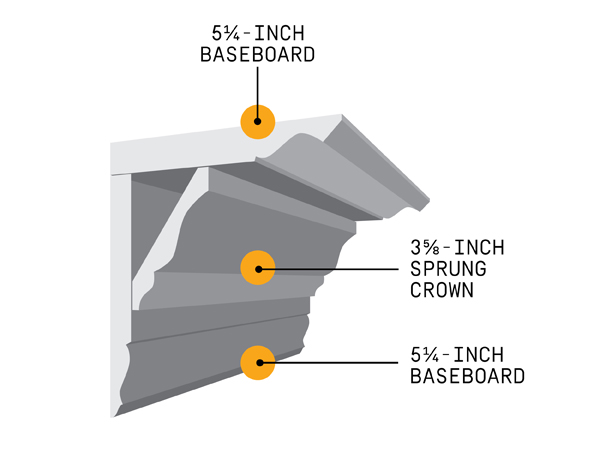

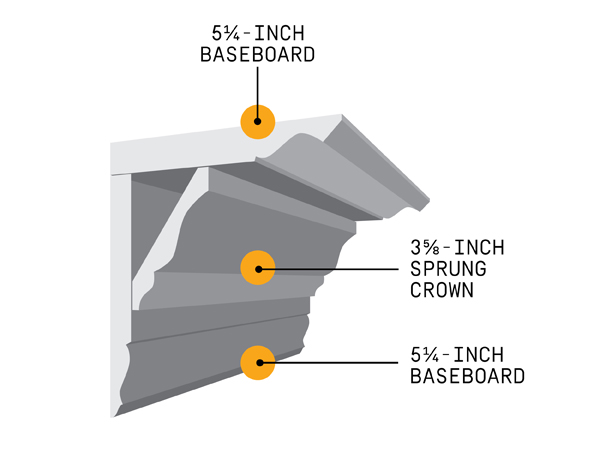

This is what I put in:

This is what I put in:

Last edited by a moderator:

snickerd3

Taking suggestions

^Way too expensive for my frugal tastes....that baseboard stuff isn't cheap

Dexman PE PMP

Internationally PMP'n his PE-ness

I forget how much I spent on it, but it was something stupid like $20/foot. We used the white plastic molding because it was cheaper. I don't want to think about how expensive real wood would have been.

Anyone know anything about basement leakage?

Our window wells fill up with water from the ground and that water leaks into our basement (unfinished). I dug around in one of the wells and there doesn't appear to be a drain (1962 house). I've had two companies come out so far with two different proposals.

Company #1 - said they will install two new window wells, dig out the earth and install pea gravel for drainage and install a drain. Tie the drains together and run out to the yard somewhere. With the window wells so deep already I'd have to imagine they would need to trench 5' to 6' deep just to get a proper slope for drainage so in my non-plumbing/water head i wouldn't think that would work very well. No warranty on the work as well.

Company #2 - said they would install an exterior drain around the house below the frost line and take that to daylight. Then install an interior drain inside and take the window well drains to those put in brand new sump pump and discharge out. He said the exterior drain is good for getting the water away from the house and the interior for taking care of whatever might end up in the house. I'm leary of busting up the basement and doing that if I haven't seen water from anywhere except the windows but I can tell that there has been water in the past from stains on the walls. I told him about Company #1 plan and he laughed and said he didn't understand how that would work (similar to the reasons I assumed it wouldn't work). Full warranty on work for life.

Our plan is to finish some of the basement in a couple of years (after this work is done and I give it a year or two to make sure it worked) so I like Option #2 from a future standpoint to just take care of everything but it also comes at a price. My parents dealt with a leaky basement for years and it was miserable throughout my childhood.

Our window wells fill up with water from the ground and that water leaks into our basement (unfinished). I dug around in one of the wells and there doesn't appear to be a drain (1962 house). I've had two companies come out so far with two different proposals.

Company #1 - said they will install two new window wells, dig out the earth and install pea gravel for drainage and install a drain. Tie the drains together and run out to the yard somewhere. With the window wells so deep already I'd have to imagine they would need to trench 5' to 6' deep just to get a proper slope for drainage so in my non-plumbing/water head i wouldn't think that would work very well. No warranty on the work as well.

Company #2 - said they would install an exterior drain around the house below the frost line and take that to daylight. Then install an interior drain inside and take the window well drains to those put in brand new sump pump and discharge out. He said the exterior drain is good for getting the water away from the house and the interior for taking care of whatever might end up in the house. I'm leary of busting up the basement and doing that if I haven't seen water from anywhere except the windows but I can tell that there has been water in the past from stains on the walls. I told him about Company #1 plan and he laughed and said he didn't understand how that would work (similar to the reasons I assumed it wouldn't work). Full warranty on work for life.

Our plan is to finish some of the basement in a couple of years (after this work is done and I give it a year or two to make sure it worked) so I like Option #2 from a future standpoint to just take care of everything but it also comes at a price. My parents dealt with a leaky basement for years and it was miserable throughout my childhood.

matt267 PE

"1000000 warning points" Club Member

- Joined

- Dec 2, 2013

- Messages

- 46,596

- Reaction score

- 3,629

@willsee, do you have a high groundwater table in your area? Have you made sure your gutter downspouts are all directed away from the house and that the grounds surface is pitched away? My inlaws had basement water issues. They had the yard regraded and now their sump pump barely runs. Its just a thought.

snickerd3

Taking suggestions

Interior drain like a french drain?

we had a leaking half below grade walkout that let water in any time it rained. The basement waterproofing contractor wanted to install a french drain to catch the water that came in, instead of finding a way to fix the problem.

we had a concrete contractor come in to look and laughed at what the other guy recommended. The concrete had settled angling towards the house. so he busted up all the concrete that was near the edge of the house and poured new concrete in bottom of the below grade stairwell with larger drain access designed such that even if it settled it wouldn't angle back towards the house. 3 yrs later and not a drop of water...we just have to deal with tiny song frogs that like to make a home under the drain grate.

we had a leaking half below grade walkout that let water in any time it rained. The basement waterproofing contractor wanted to install a french drain to catch the water that came in, instead of finding a way to fix the problem.

we had a concrete contractor come in to look and laughed at what the other guy recommended. The concrete had settled angling towards the house. so he busted up all the concrete that was near the edge of the house and poured new concrete in bottom of the below grade stairwell with larger drain access designed such that even if it settled it wouldn't angle back towards the house. 3 yrs later and not a drop of water...we just have to deal with tiny song frogs that like to make a home under the drain grate.

Yeah interior french drain.

That's a good idea Matt. I've left messages with a couple of landscape contractors to get their thoughts. Our sump runs pretty frequently and we have areas of yard that don't drain very well, so maybe if I get them out there they might have some ideas that don't involve busting up what seems like a fine basement aside from the leaking window wells.

That's a good idea Matt. I've left messages with a couple of landscape contractors to get their thoughts. Our sump runs pretty frequently and we have areas of yard that don't drain very well, so maybe if I get them out there they might have some ideas that don't involve busting up what seems like a fine basement aside from the leaking window wells.

Dexman PE PMP

Internationally PMP'n his PE-ness

Sub-floor drains only work if they have somewhere to drain to that is drier than where they are draining from. If they are running under the basement floor, you're only real option is to tie it into the house sewer line or to a sump pump/pit. Otherwise it will be trying to discharge into somewhere that is surcharged.

I would start with the grades around the perimeter of the building and making sure everything within 5-8 feet drain away from the house (5% grade on landscaping, 2% min on impervious surfaces). In the city I live, they require the grade within 10' of the house has to be 10% (only 2% if it's impervious).

I would start with the grades around the perimeter of the building and making sure everything within 5-8 feet drain away from the house (5% grade on landscaping, 2% min on impervious surfaces). In the city I live, they require the grade within 10' of the house has to be 10% (only 2% if it's impervious).

Last edited by a moderator:

wilheldp_PE

PE, LEED AP, SPAM KING

Is the second contractor a plumber or just a foundation repair or landscaping firm? If it's the former, you could have them rough in plumbing for a bathroom in your basement while they are down there busting up concrete for the french drain. That way, you only have to clean up concrete dust/mess once, and you don't have to worry about the plumbing when you get around to finishing the basement.Yeah interior french drain.

That's a good idea Matt. I've left messages with a couple of landscape contractors to get their thoughts. Our sump runs pretty frequently and we have areas of yard that don't drain very well, so maybe if I get them out there they might have some ideas that don't involve busting up what seems like a fine basement aside from the leaking window wells.

This is going as trim on top of a window cornice, so I don't have the luxury. Though I will be using caulk a plenty anyways. It doesn't help that something crapped out on my 10" saw and it won't cut at a 90 anymore. Probably should just dump it and pony up for the Hitachi one.^^^ Just use caulk to fill the gaps. You need it to fill the nail holes anyways. All my crown molding is 9' up, no one can tell a difference.

Similar threads

- Replies

- 7

- Views

- 9K