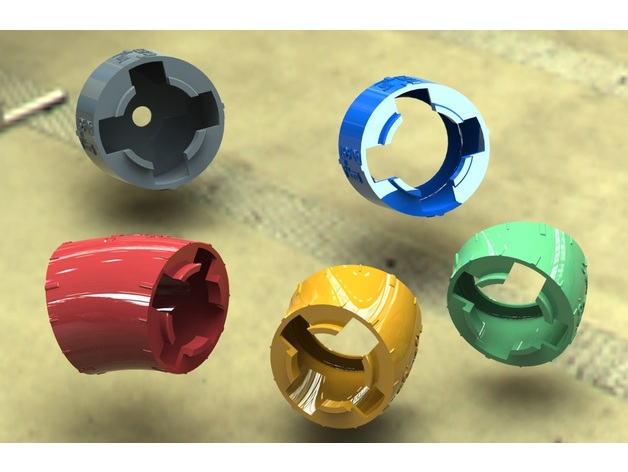

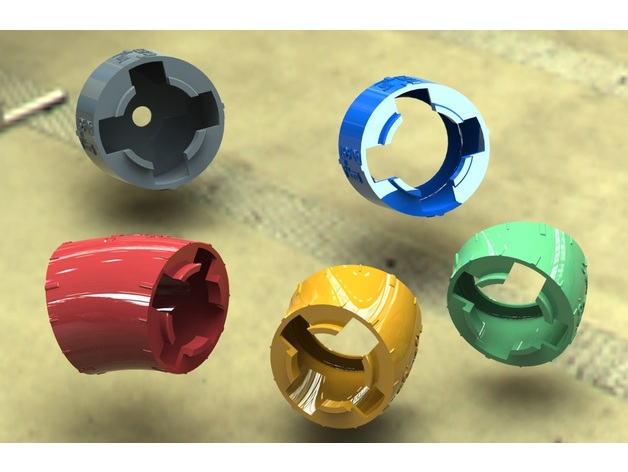

Any 3D printer users on board? Starting to look at some options for a 300x300x300mm printer in the sub-$500 range. Intended purpose is mostly small clamps/brackets/housings for parts for the race car, but also some building block style header mockup parts:

Any recommendations? I've looked at the Creality CR-10, the Anycubic i3 Mega, and the Creality Ender 3, but everything at that price point has completely polarizing reviews until you get into the smaller beds. I really want that 300mm capability (at least width, could deal with shorter height) in order to make some glare hoods/brackets for some parts that are at least 8-10" in length.

Any recommendations? I've looked at the Creality CR-10, the Anycubic i3 Mega, and the Creality Ender 3, but everything at that price point has completely polarizing reviews until you get into the smaller beds. I really want that 300mm capability (at least width, could deal with shorter height) in order to make some glare hoods/brackets for some parts that are at least 8-10" in length.