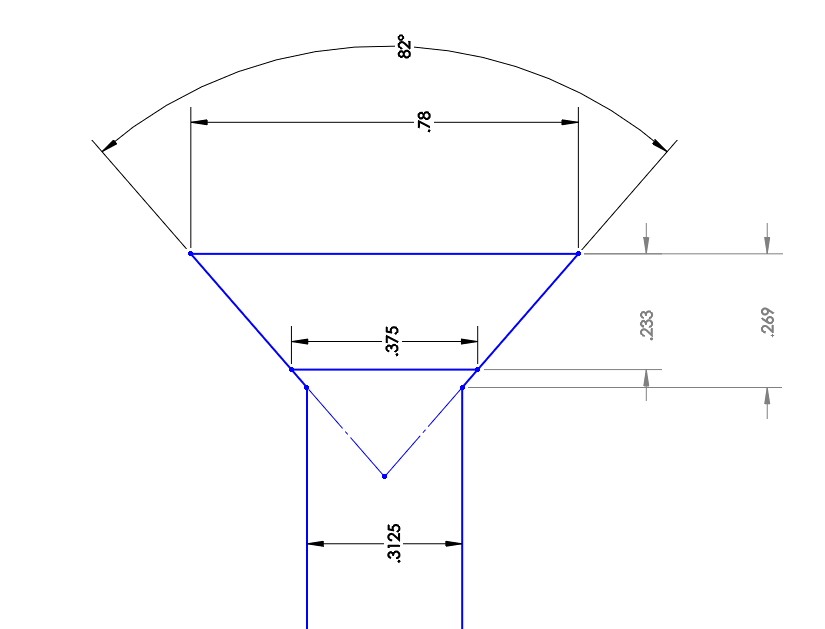

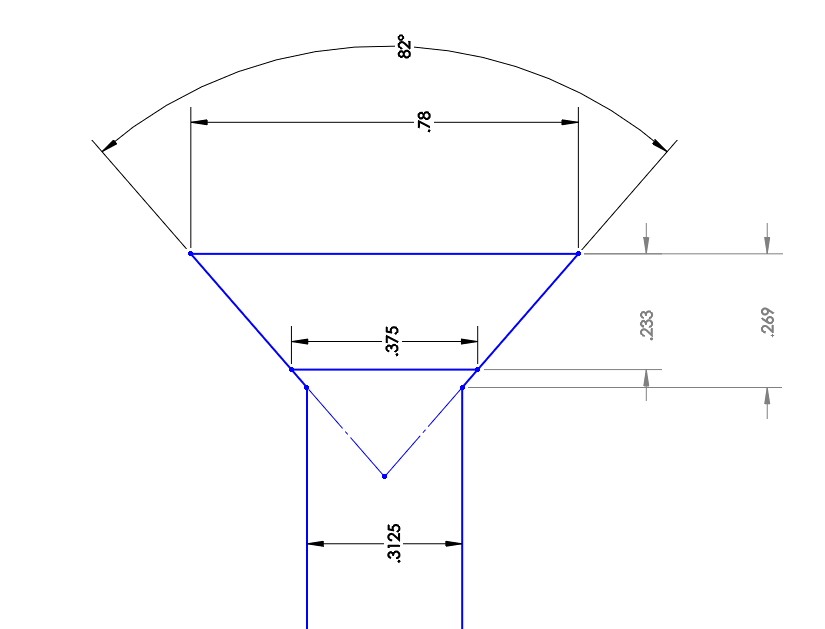

This seems like one of the easier questions, but the answer doesn't make sense to me. It uses more geometry than T&F. The screw won't fit until the hole is tapped in step 3, but the solution uses the hole initially drilled from step 1. I get .233 (B) as my answer since 3/8 + 2*.233 = .78.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2016 Practice Exam T&F problem 104

- Thread starter Viper5

- Start date

Help Support Professional Engineer & PE Exam Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

JHW 3d

Here's Johnny...

Post problem?This seems like one of the easier questions, but the answer doesn't make sense to me. It uses more geometry than T&F. The screw won't fit until the hole is tapped in step 3, but the solution uses the hole initially drilled from step 1. I get .233 (B) as my answer since 3/8 + 2*.233 = .78.

Audi Driver P.E.

Well-known member

- Joined

- Sep 21, 2015

- Messages

- 4,851

- Reaction score

- 1,675

It's because the measurement is to the hole edge that exists prior to the tap. Perhaps this sketch will help you understand why your approach is wrong. Note that the dotted lines represent the CSK drill. What the problem is asking for is where does the CSK drill intersect the drilled hole:

JHW 3d

Here's Johnny...

Audi is on the right track. Still, I hate this question. It is not actually practical. Manual drilling for a csk, you go down as far as required until the csk dia is correct. For a cnc machine, the depth would be defined against the csk tip.

And this is not to mention: how many csk holes are tapped??

And this is not to mention: how many csk holes are tapped??

Audi Driver P.E.

Well-known member

- Joined

- Sep 21, 2015

- Messages

- 4,851

- Reaction score

- 1,675

Agree, it's a terrible question for all the reasons you mention. But, for a simple math problem, what they want to know is can you pay attention to detail. And in a person's study prep, you need to practice finding what it is they're actually looking for. There's some extraneous data to sift through in this problem and that is a good thing to practice because they do that a lot on the exam questions.Audi is on the right track. Still, I hate this question. It is not actually practical. Manual drilling for a csk, you go down as far as required until the csk dia is correct. For a cnc machine, the depth would be defined against the csk tip.

And this is not to mention: how many csk holes are tapped??

Last edited by a moderator:

Audi Driver P.E.

Well-known member

- Joined

- Sep 21, 2015

- Messages

- 4,851

- Reaction score

- 1,675

Also, if the CNC isn't used to tap the hole as well, then it's a good idea to check to see if you have the proper geometry before moving on to the next step. Arguably what you would measure, though, is the CSK diameter. Because assuming you have an 82 deg CSK, you're going to get the correct depth to edge.

It's also a bad question because anyone who has ever done this knows that you're not going to end up with a flush screw if you size the CSK exactly to the screw geometry.

It's also a bad question because anyone who has ever done this knows that you're not going to end up with a flush screw if you size the CSK exactly to the screw geometry.

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 13

- Views

- 11K

- Replies

- 33

- Views

- 10K

- Replies

- 0

- Views

- 6K

Latest posts

-

-

-

-

-

For Sale CA Civil Seismic - AEI Review & Practice Exams Books - Newest Editions

- Latest: wellhellothere gen kenobi

-

-

-